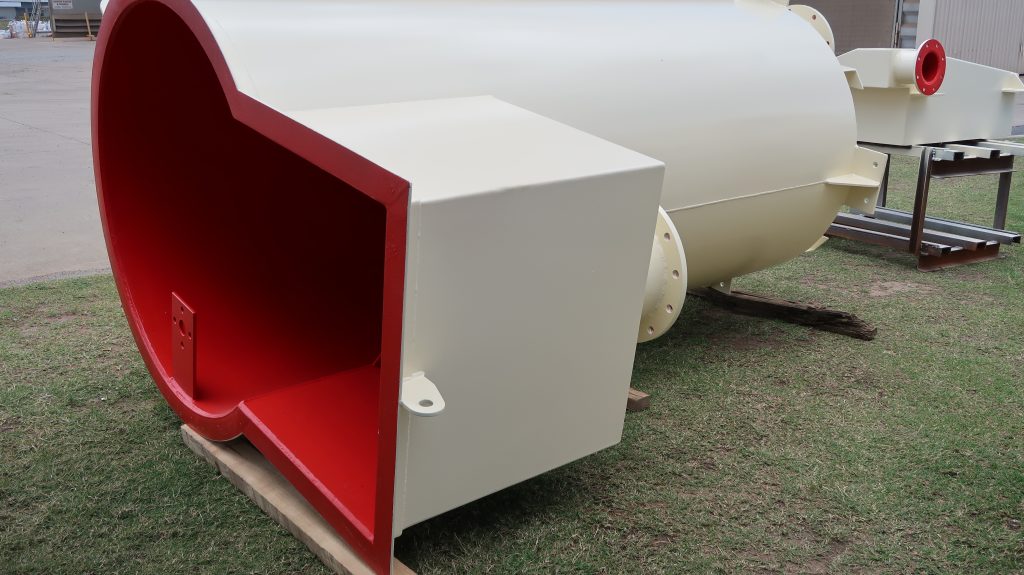

Blast and Paint, Industrial Tiling & Poly Spray Services DGH delivers a complete range of blast and paint, poly spraying and industrial tiling services. Our focus is on providing practical, high quality solutions that protect and extend the life of equipment, steel structures and industrial spaces. From abrasive blasting and protective coatings through to poly … Continue reading Blast and Paint, Industrial Tiling & Poly Spray Services